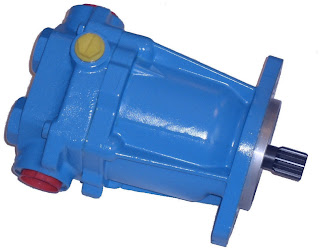

Rexroth Hydraulic Pumps

The mechanical device that is used to convert mechanical power into hydraulic energy is known as a hydraulic pump. These types of Pums are mainly used to push the fluid into the hydraulic system.The hydraulic pump design, manufacturing and leading-edge pump innovation theme goes to the global leader Bosch Rexroth.

Hydraulic Pumps Range:

- Bent Axis Pumps

- Swash plate Pumps

- Gear Pumps

- Vane Pumps

- Radial Piston Pumps

Bent Axis Pumps

This type of offers high power density with good compact design and moreover its cost-effective. It is designed in a economical manner providing more power/weight ratio for efficiency operations. That is the main reason people use this one for heavy duty operations.

Advantages:

Positive displacement, High pressure, heavy duty applications.Swash plate Pumps

This is a model which is mainly used in axial-piston hydraulic pumps to convert translational motion of a piston into rotational motion of a drive shaft. During the first half revolution the piston sucks the fluid and the next half it just pushes out.

Advantages:

Positive displacement, High pressure, heavy duty applications with high efficiency.Gear Pumps

To pump out fluids with certain viscosity in chemical installations gear pumps are mainly used. This can be differentiated into two types. External gear pumps, uses two spur gears externally, the other is internal gear pumps which uses both external and internal spur gears.

Advantages:

Positive displacement, High speed, High Pressure.Vane Pumps

A Vane Pump is a Positive Displacement Pump (PDP) with a vaned rotor that is positioned topsy turvy inside a tube shaped chamber. The vanes slide done and finished as the rotor turns. Pumping activity is brought on by the volume updates in the middle of sharpened pieces of steels.

Advantages:

Positive displacement, can handle low viscosities.

Radial Piston Pumps

In a spiral cylinder pump, the working cylinders are organized in outspread heading, and the stroke of the cylinder is determined by an unusual shaft or an outer flighty cam. Radial piston multi-flow pumps are capable of withstanding a maximum operating pressure of up to 350 bar, depending on the model.

Advantages:

Rated high pressure, high speed, large power-driven pump.Conclusion:

Nowadays manufacturers and dealers are up-to-date with latest technologies. They have highly trained professionals to test their product with good quality and also to withstand high pressure. This turns up visitors into buyers and satisfied customers relationship.

For more information visit us @ PanagonSystems.

For more information visit us @ PanagonSystems.