The hydraulic cylinder is a dangerous equipment so it has to be protected with the safety locks in order to avoid with the injury of the person. When setting for the operation they need the valves on either end to support with the proper fluid flow. These types of the machines are commonly used in the automation industry. Usually the manufacturers like Eaton hydraulics concentrate on the bent rods as this holds the arrangement in the right balance. On the other hand if the system is not working properly then you can check with the cylinder tubes for any blockage and then rectify it.

Problems With Hydraulic Cylinder

- The main issue occurs with the seal so after each operation they have to be cleaned.

- Check for the lubrication regularly to avoid the contamination.

- The interface has to be checked for the hydraulic supply system fluid and then they have to be made compatible.

- If you are using it for a long time then you can come across some cracks in it.

|

| Hydraulic Cylinder |

In case of any repair, you can call for the technician as they will disassemble all the parts, remove the piston and then check for the issue.

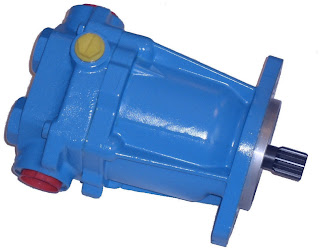

Piston Pumps

The piston pumps are placed inside the cylinder so you can easily adjust its speed by using the thermostat present in it. Since they work on the centrifugal force the loaded valves are getting diminished with the it has a meter placed inside so you can check the output power and then generate the efficiency ratio.

The pumps are cleaned with the special detergent or chemicals to remove the dirt and the debris present in it. When the pump rotates the volume of the liquid decreases with the smooth pressure exerted on it. If the position sensor is moved then you get some faults in the application along with the installation benefits. At that time the hand pumps are being used based on the capacity of the cylinder.

Applications And Features Of Piston Pumps

They are highly flexible and easily portable too as it is used in the large scale industries for the rugged operation. By applying a higher pressure of water in the piston you can wash away the dirt in it. Whatever might be the usage you can go with the reputable company to meet with the demands of the industry. The ceramic plungers used are quite expensive.

No comments:

Post a Comment